| Anber Wire Mesh & Machine Factory |

|

Manufacturer of Wire Mesh and Wire Mesh Machine: expanded metal machine, angle bead machine, its finished products, etc. |

-

Wire Mesh Machine

- Welded Wire Mesh Machine

- Truss Girder Welding Machine

- Wire Drawing Machine

- Angle Beads Machine

- Plaster Stop Machine

- Brickwork mesh Machine

- Rib Lath Making Machine

- HY-Rib Mesh Machine

- Expanded Metal Mesh Machine

- Barbed Wire Machine

- Hexagonal wire netting machine (Gabion mesh machine)

- Chain Link Fence Machine

- PVC coating line

-

Wire Mesh Products

- Welded Wire Mesh

- PVC Coated Wire

- Angle Beads (Corner Beads)

- Plaster stop

- Brickwork reinforcing mesh

- RIB LATH

- HY-Rib Formwork Mesh

- Hexagonal Wire Netting

- Expanded Metal Mesh

- Barbed Iron Wire

-

Anber Contacts:

Tel: +86-510-88239310

88239309

| Home page | Wire Mesh machine | Mesh welding machine | PVC coating line | Online Order | Contact Us |

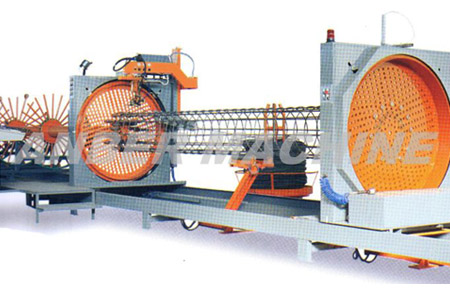

Roll Welding Machine/Pilemaster:

According to the construction requirements, longitudinal bar is feed through the hole on the fixed rotating disk by human and get fixed, weld one head of the stirrups to the longitudinal bar, and the rotating disk will wind and move back for fixed distance to weld to spiral bar to the longitudinal bar, this is how the pile cage (also named welded cage, reinforcement cage) to be formed.Precision of the welded cage: The reinforcement cage needs high precision of the spacing of the stirrups. This pilemaster (cage welding machine) sets stirrups spacing through PLC, so can promise high precision. Actually the stirrups distance is influenced by the rotating speed and moving speed, so in the control of PLC, there will be no need to worry about.

Characteristic Features

♦ High production rate:

Normally it requires 10 worker, devided into two work shifts, to assist in feeding, welding and inner rings installation. With the help of these 10 worker, this machine can produce at least 20 finished cages one day.

♦ Stable cage quality:

Compared with manual cage making, mechanization production can reach to better cage quality with regular spiral pitch, thus the finished cages share the same diameter and shape. Their quality completely accords with expected standards.

♦ Low production cost:

Compared with manual cage making, there is no need for mechanization production to fix inner ring at longitudinal bars with wire, which can save 1% material cost.

♦ Short hoisting time:

With the help of template, longitudinal bars are evenly placed on the circumference. So that it is easy to lap joint two cages and can save hoisting time.

|

|

|

| Pile cage making machine | Roll welding system | Pile cage roll welding machine |

|

|

|

| Pile cage output system | Bored pile cage welding machine |

| Item | 1500 Model 12+2 Size | 2500 Model 18+2 Size |

| Longitudinal bar dia. | 12mm-40mm | 12mm-40mm |

| Spiral bar dia. | 5mm-16mm | 5mm-16mm |

| Spiral pitch | 50mm-450mm (adjustable) | 50mm-450mm (adjustable) |

| Power | 13KW (including feeding device) | 20KW (including feeding device) |

| Overall dimensions | 29m×2m×2.2m (L×W×H) | 43m×3m×3.5m (L×W×H) |

| Total weight | 12T | 23T |

Our Wire Mesh Machine Products Catalog:

Our Wire Mesh Products Catalog:

| • Welded Wire Mesh | • PVC Coated Wire | • Corner Beads (Angle Beads) | • Plaster stop |

| • HY-Rib Formwork Mesh | • RIB LATH | • Hexagonal Wire Netting | • Expanded Metal Mesh (Diamond Metal Mesh) |

| Anber wire mesh machine | Anber Expanded Metal Mesh Machine | Rib lath machine | Mesh welding machine | Wire drawing machine |