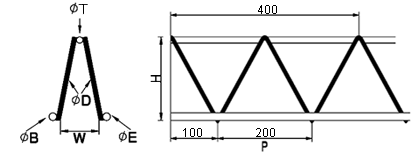

Truss girder/lattic girder welding machine:

Truss girder welding machine has a high production capacity with its maximum speed of some 12 linear meters per minute of finished cut and stacked girder. This high production capacity and overall quality of the plant is well balanced with the machine's price tag.

The truss girder plant can easily be operated by one person.

The truss girder welding machine consists of Pay off system, Straightening & unwinding unit, Loop control cages, Straightening rollers, Central machine, Diagonal forming chains, Welding stations, Advancing cart, Girder shearing unit, Girder consignment, Evacuation & automatic stacking unit, Controlling cabinet, Overhead control console, Switching cabinets

|

|

|

| Pay off system |

Straightening unit |

Inclined beading bending & molding structure |

|

|

|

| Welding system of the lattic girder welding plant |

Shearing part of truss girder production line |

Control system |

| Item |

ABE-YJ300A |

ABR-YJ300B |

| Diagonal wire diameter |

φ 5-8mm |

φ 5-8mm |

| Longitudinal wire diameter (lower) |

φ 8-12mm |

φ 8-12mm |

| Longitudinal wire diameter (upper) |

φ 8-12mm |

φ 8-12mm |

| Girder internal base width |

50-320mm (can be designed) |

50-320mm (can be designed) |

| Girder internal base height |

50-150mm (can be designed) |

50-150mm (can be designed) |

| Length of the truss girder |

Multiples of 200mm |

Multiples of 200mm |

| Power of the transformer |

4*175KVA |

4*200KVA |

| Other power |

75KW |

80KW |

| Output (maximum) |

12m/min |

12m/min |

| Length of the truss girder production line |

42m |

42m |

|

|

Our Wire Mesh Machine Products Catalog:

Our Wire Mesh Products Catalog: