| Anber Wire Mesh & Machine Factory |

|

Manufacturer of Wire Mesh and Wire Mesh Machine: expanded metal machine, angle bead machine, its finished products, etc. |

-

Wire Mesh Machine

- Welded Wire Mesh Machine

- Truss Girder Welding Machine

- Wire Drawing Machine

- Angle Beads Machine

- Plaster Stop Machine

- Brickwork mesh Machine

- Rib Lath Making Machine

- HY-Rib Mesh Machine

- Expanded Metal Mesh Machine

- Barbed Wire Machine

- Hexagonal wire netting machine (Gabion mesh machine)

- Chain Link Fence Machine

- PVC coating line

-

Wire Mesh Products

- Welded Wire Mesh

- PVC Coated Wire

- Angle Beads (Corner Beads)

- Plaster stop

- Brickwork reinforcing mesh

- RIB LATH

- HY-Rib Formwork Mesh

- Hexagonal Wire Netting

- Expanded Metal Mesh

- Barbed Iron Wire

-

Anber Contacts:

Tel: +86-510-88239310

88239309

| Home page | Wire Mesh machine | Mesh welding machine | PVC coating line | Online Order | Contact Us |

| 3D Truss girder welding machine | 2D Truss girder welding machine |

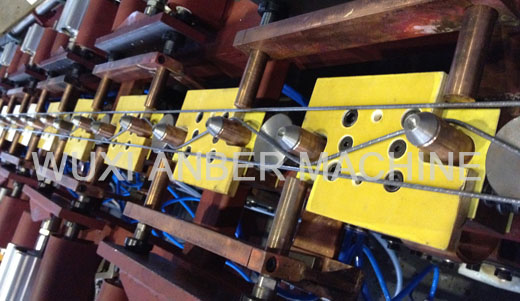

2D lattice Girder Welding Machine :

The 2D lattice girder welding machine has a production capacity with its maximum speed of some 6 linear meters per minute of finished cut and stacked girder. This high production capacity and overall quality of the plant is well balanced with the machine's price tag.The flat lattice girder welding plant can easily be operated by one person.

Characteristics

♦ The plant is controlled with a system which is reliable, powerful and flexible and controls all the functions of the machine and allows an easy interface with the operator. The main computer has a diagnostic system which allows an immediate check of all the signals emanating from the machine.

♦ All the axis parameters, machine times and speeds are adjustable from the computer.

♦ The programming is quick and easy so as to be as user friendly to the operator as possible.

♦ The welding is controlled by units which allow the operator to adjust and change the periods and the power relative to the production at hand.

♦ All the power apparatuses for driving the motors and all other functions are mounted in the electronic switching cabinets; all the signal lights and the various commands are found on the cabinets.

The operator controls the plant through the electronic control stations which are positioned appropriately.

|

|

|

| Truss girder welding lines | The 2D lattice girder welding machine | Flat truss girder machine |

|

|

|

| Semi-auto flat truss girder welding machine |

Low carbon steel wire truss girder welding machine |

| Power supply voltage | 380V ± 10% – 50Hz±1% | |

| Installed power-welding | 300KVA (Average consumption 80KVA) | |

| Air | Consumption (filtered, dried, no water, no oil) | 3.5m ³/min |

| Operational pressure (constant) | 0.8Mpa | |

| Water | Consumption (clean, filtered, no residues, no calcium, no deposits) | 3.5m³/min |

| Min pressure (constant) | 0.2 – 0.3Mpa | |

| Max temperature at inlet | 30°C | |

| Ambient conditions* | Temperature | 0 – 40°C |

| Altitude | <1000m.a.s.l. | |

| Material type | FeB44K, FeB32K, FeB38K (weldable) | |

| Unitary yield stress | Max 600N/mm² | |

| Unitary tensile stress | Max 700N/mm² | |

| Elongation | >14% | |

| Longitudinal wire diameter (upper) | 5-10mm | |

| Longitudinal wire diameter (lower) | 5-10mm | |

| Diagonal wire diameter | 3-8mm | |

| Production rate (maximum) | 6m/min | |

| Girder height | 70mm– 350mm (min >100mm forΦlong.=10mm) | |

| Girder internal base width | 60mm–100mm | |

| Pace/stroke | 400mm/weld | |

| Diagonal spacing | 200mm | |

| Girder length | Max 6m , Min 1.6m (STD.) | |

Our Wire Mesh Machine Products Catalog:

Our Wire Mesh Products Catalog:

| • Welded Wire Mesh | • PVC Coated Wire | • Corner Beads (Angle Beads) | • Plaster stop |

| • HY-Rib Formwork Mesh | • RIB LATH | • Hexagonal Wire Netting | • Expanded Metal Mesh (Diamond Metal Mesh) |

| Anber wire mesh machine | Anber Expanded Metal Mesh Machine | Rib lath machine | Mesh welding machine | Wire drawing machine |